|

Teck

Cominco Riverbank Restoration Project

Go To:

Implementation/Construction

Repair

and Maintenance

Monitoring

Results

Compost Tea

Application

Introduction:

In December of 2004 Terra Erosion Control Ltd,

in association with Amec Earth Environmental, competitively

won the contract to develop a prescription and cost

estimate for the riverbank restoration project. In 2005

Terra Erosion Control Ltd was retained to implement

the prescribed treatments from 2006 to 2008.

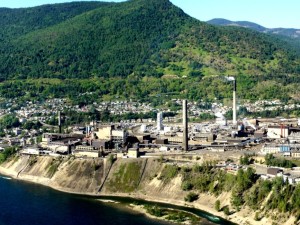

Location:

Riverbank

and hillside adjacent to the Teck Cominco lead-zinc

smelter and the Columbia River in Trail, BC.

Client:

Teck

Cominco Metals Limited

Objective:

Establish vegetation on the hillside and adjacent riverbank

below the lead-zinc smelter in order to reduce/control

soil erosion and improve visual, wildlife and fish habitat

values.

Teck Cominco

and it's predecessor have operated a smelter in Trail

since the later 1800's. Evidence of the long operation

can be found on the slope below the smelter with the

presence of bricks, smelter slag, metal bits and a variety

of other materials. A

number of previous attempts to re-vegetate the area

have been made; in general these have been met with

poor to, at best, moderate success. The current project,

which uses soil bioengineering techniques, is expected

to yield a more satisfactory solution.

For

this project the hillside below the smelter was divided

into four treatment units and the adjacent riverbank

into five treatment sections. Live cuttings used in

the soil bioengineering structures were collected locally

starting in the fall of 2005.

|

|

Tech Cominco

smelter, 1930's (photo: Ministry of Environment, Nelson,

B.C.)

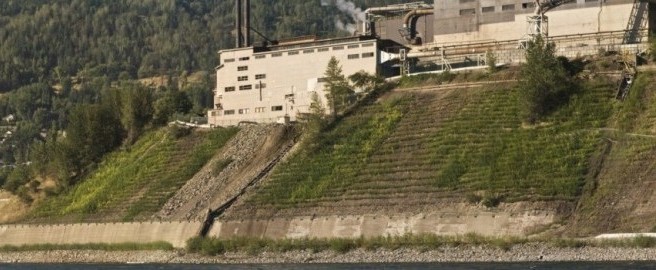

Hillside

Unit 1 and riverbank 2004, pre-treatment (photo: Amec

Earth and Env.)

|

Hillside Units 1 and 2

and riverbank 2004, pre-treatment (photo: Amec Earth

and Env.)

|

Hillside Units 2 and 3

and riverbank 2004, pre-treatment (photo: Amec Earth

and Env.)

|

| |

Hillside

Units 3 and 4 and riverbank 2004, pre-treatment (photo:

Amec Earth and Env.)

|

2005 Aerial

photo of hillside, pre-treatment (photo: Teck Cominco

Metals Ltd.)

|

| |

|

Implementation/Contruction:

Riverbank

Sections: In

the spring and fall of 2006 soil bioengineering structures

were installed along the Columbia River . These consisted

primarily of brush layers, but also brush sills in combination

with live fascines and vegetated rip-rap. The species

component of these structures consisted of a mixture

of Willow ( Salix bebbiana / scouleriana / exigua

), Black Cottonwood ( Populus balsamifera ssp.

trichocarpa ), Red-Osier Dogwood ( Cornus stolonifera

), and a small amount of Pacific Willow ( Salix

lucida ssp. lasiandra ). Planting was machine-assisted

using an excavator.

A

section of the brush sill / fascine structures was destroyed

in spring 2008 due to extension of the riverbank road.

During construction a vegetated rip-rap application

was installed along this new section of road containing

a high component of Pacific Willow (medium sized tree).

It is intended to provide a visual filter for the wall

located behind the road.

A

total of approximately 27,000 live cuttings were planted

in Sections 1 to 3A, between 2006 and 2008, over an

area of 0.5 ha.

| |

|

Vegetated

riprap installation riverbank,

spring

2006

|

Machine assisted brush layers installation riverbank,

spring 2006

|

| |

|

| Hillside

Units: Installation

of soil bioengineering structures on the hillside

units commenced in fall 2006 (Units 3 and 4),

continued in spring 2007 (Units 2, 3 and 4), and

was completed in spring 2008 (Unit 1). Two small

areas in Unit 4, with a slope gradient less than

40 %, were planted using an excavator. In areas

with slopes greater than 40 % (the bulk of these

units), machine-assisted planting was done using

a walking excavator (Spyder Hoe). On slopes greater

than 60 % this machine was tethered to a skidder

located at the top of the slope. Materials were

either transported up the slope using an overhead

cable system (Units 2 to 4), or lowered down onto

the slope using a cable / buggy system (Unit 1).

The

soil bioengineering structures consist of brush

layers planted using a mixture of Black Cottonwood

and Willow species. Straw wattles were also installed

across the slope between every second brush layer.

These are designed to disperse surface water and

act as sediment traps, reducing the risk of surface

flow leading to rill erosion. The hillside units

were also planted with native shrubs and conifer

trees and hydro-seeded with native grasses. Due

to the dry conditions on this site during the

summer, an irrigation system was installed over

all areas.

In

2007, trials using pulp-mill biosolids as a soil

amendment were carried out in the more contaminated

areas of Unit 3. Due to favourable results obtained

here, this material was used extensively in Unit

1 (2008) during brush layer installation in areas

where the soil had higher levels of contamination.

A total of 300 cubic meters of this material was

applied to this unit.

A

total of approximately 148,000 live cuttings,

11,900 shrubs and tree seedlings were planted

in Units 1 to 4 between 2006 and 2008 over an

area of 3.29 ha.

|

Vegetated riprap

installation riverbank,

spring

2008

|

Brush

layer planting with excavator in Unit 4, spring

2006

|

| |

|

Brush

layer planting with Spyder Hoe in Unit 3, spring

2007

|

Brush

layer planting with Spyder Hoe in Unit 3, spring

2007

|

Placement

of biosolids on slope on slope of Unit 1, spring

2008

|

Brush

layer planting in Unit 1, spring 2008

|

| |

|

Brush layer planting in Unit 1, spring 2008

|

Straw wattles installed to control surface erosion

|

| |

|

Cable

system used to transport materials onto

slope

Unit 4, spring 2007

|

Cable/buggy

system used to transport materials

onto

slope Unit 1, spring 2008

|

| |

|

| Repair

and Maintenance:

Due

to surface rill erosion in some areas, resulting

mainly from irrigation water flowing over soil

with poor grass cover (due to soil toxicity),

repair / maintenance treatments were needed on

the hillside units in the spring and fall of 2008.

These consisted primarily of placing coir matting

over critical areas and the installation of additional

straw wattles, some of which included burlap splash

aprons (these aprons improve the effectiveness

of wattles in steep areas).

|

| |

|

Coir

matting placed on critical area at top of slope,

spring 2008

|

Straw

wattles with burlap aprons in Unit 2, September

2008

|

| |

|

Straw

wattle with burlap apron, September 2008

|

| |

|

| Monitoring

Results:

Riverbank

Sections: As

of August 2008, survival and growth of the soil

bioengineering structures installed in the riverbank

sections has been good to excellent overall. In

some areas, however, survival was reduced due

to prolonged river flooding. When the brush layers

were submerged by water during flooding, survival

was still good if the top of growing shoots remained

above the water. Additional monitoring took place until the Fall of 2014. |

Riverbank

Section 1, May 2008

|

Riverbank Section

1 South, summer 2010

|

| |

|

Riverbank Section 1 North, summer 2010

|

|

|

| |

|

Riverbank Section

1A, summer 2008

|

| |

|

Riverbank Section 1A South, August 2008 |

|

|

| |

|

Riverbank

Section 2 during flooding, spring 2007

|

Riverbank

Section 2, August 2008

|

| |

|

Riverbank

Section 1 & 2, September 2008

(photo:

Teck Cominco)

|

Riverbank

Section 3, August 2008

|

| |

|

Riverbank

Section 3 & Unit 4 above road, August 2008

(photo: Teck Cominco)

|

| |

|

| Hillside

Units 2 to 4: Survival

and growth of brush layers planted in Units 2,

3 and 4 was highly variable when assessed in August

2008 (these brush layers had two seasons of growth

at this time). The average survival rate of planted

cuttings, based on data collected in 11 permanent

sampling plots, was 42 %. This value is considered

only a rough estimate, as the S. D. (24 %) and

range (7 % to 86 %) were high. Some areas with

very good survival and growth were present, along

with areas with very poor survival and growth.

High mortality in some areas is thought due to

one or more of the following: high soil metal

concentrations, very hot and dry conditions during

the summer of 2007 combined with poor irrigation

coverage, heavy grass competition, and high soil

salinity levels. |

| |

Hillside

Unit 2, August 2008

|

Hillside

Unit 3, August 2008

|

| |

|

Hillside

Unit 3, August 2008

|

Hillside

Units 2 and 3, August 2008

|

| |

|

Hillside

Units 2 and 3, August 2008

|

Hillside

Unit 4, August 2008

|

| |

|

Hillside

Unit 4, August 2008

|

| |

|

| Unit

1: Survival

and growth of brush layers in Unit 1 was very

good when assessed in August 2008. Based on data

collected in six permanent sampling plots, the

average survival rate of planted cuttings was

87 % (S.D. 6 %). The application rate of biosolids

in areas with highly toxic soil was highly variable

– this could be seen in the patchy colour (dark

green patches next to chlorotic patches) of foliage

in these areas. |

| |

Hillside

Unit 1 North, August 2008

|

Hillside

Unit 1 South, August 2008

|

| |

|

Hillside

Unit 1, August 2008

|

| |

Section 1, summer 2010

|

| |

Section 1A, summer 2010

|

| |

Section 1, 1A and 2, summer 2010

|

| |

| Monitoring: Monitoring

of the riverbank and hillside units was completed in the Fall of 2014. |

Unit 1 Fall 2013

|

| |

|

Unit 1 South, Fall 2014

|

| |

|

Unit 3 Fall 2014

|

|

|

Unit 3 Salix lasiandra Fall 2013

|

Unit 3 Salix lasiandra Fall 2013

|

| |

|

Section 1 Fall 2014

|

Section 1 Fall 2014

|

| |

|

Section 1 Fall 2014

|

Section 1A Fall 2014

|

| |

|

Section 3 Fall 2014

|

Section 3 Fall 2014

|

| |

|

Before, 2006

|

| |

|

Hillside Fall 2014

|

| |

|

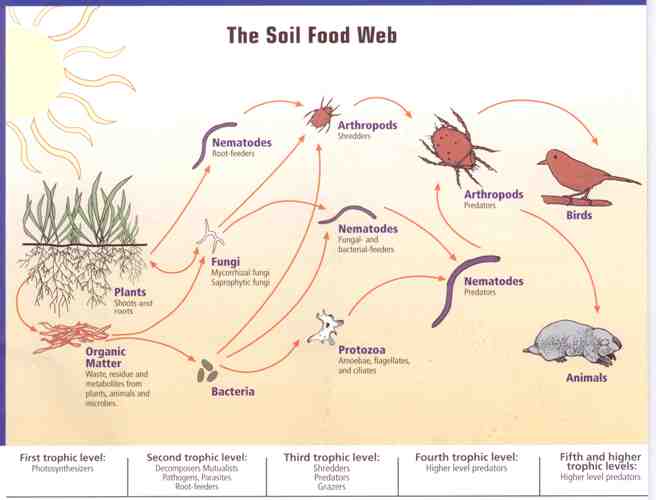

| Compost

Tea Application:

The

importance of a healthy soil (and foliar) microbial

community to proper ecosystem functioning is well

recognized. Compost tea is a technology developed

to help replenish and restore this community on

lands where it is degraded – plant growth is typically

improved with tea applications containing the

correct mix of beneficial organisms for the vegetation

being grown (Ingham, 2005). Compost Tea production

is a “cold brewing” process, allowing growth of

organisms extracted from the compost. Various

organic foods / organic fertilizers are added

during the brewing process to provide food &

nutrient substrates for the microbial organisms

to grow. The degree to which fungal growth, versus

bacterial growth, is sustained during the brewing

process will depend on the quality of the initial

compost used and the type of food / nutrients

added. It is important that the process remain

aerobic during the brewing process and up until

the tea is applied – if the tea becomes anaerobic,

beneficial organisms (aerobic fungi, protozoa

and nematodes) may be lost, replaced by anaerobic

bacteria and yeasts (Ingham, 2005).

Given

the contaminated nature of the soil and lack of

vegetation in the Riverbank Restoration Project

area prior to the present reclamation treatments,

restoration of the microbial community here is

considered a vital component of the project. To

help achieve this, three compost tea applications

are scheduled for each year until 2011. As of

fall 2008, five compost tea applications have

been done (two in 2007 and three in 2008). The

compost tea is applied through injection into

the irrigation system.

|

Brewing

compost Tea

|

Injection

of compost tea into irrigation system

|

| |

|

A

Soil Foodweb Drawing (Drawing: USDA-NRCS)

|

| References

Cited:

Ingham,

E. (2005). The Compost Tea Brewing Manual, 5 th edition.

Soil Foodweb Incorporated, Corvallis , Oregon .

|

Copyright © 2010

Terra Erosion Control Ltd.

Riverbank Restoration Project ~ Teck Cominco

|

|

|

|